3D printing, also known as additive manufacturing, has emerged as a transformative technology with the potential to revolutionize numerous industries. By enabling the creation of complex and customized objects layer by layer, 3D printing offers unprecedented flexibility, efficiency, and innovation. This article explores how 3D printing is shaping future solutions across various sectors, highlighting its applications, benefits, challenges, and the promising trends that lie ahead.

To grasp the full impact of 3D printing, it is essential to understand the technology’s fundamentals and its evolution over the years.

1. What is 3D Printing?

3D printing is a process that creates three-dimensional objects from digital models. Unlike traditional manufacturing methods that often involve subtractive processes—where material is removed from a solid block—3D printing builds objects by adding material layer by layer based on precise digital instructions.

- A. Additive Manufacturing: This refers to the core principle of 3D printing, where material is added in successive layers to form an object.

- B. Digital Design Integration: 3D printing relies heavily on digital design software, allowing for intricate and precise designs that are difficult to achieve with conventional methods.

- C. Material Diversity: Various materials can be used in 3D printing, including plastics, metals, ceramics, and even biological materials, expanding its applicability across different fields.

2. Evolution of 3D Printing

3D printing technology has advanced significantly since its inception in the 1980s, transitioning from industrial applications to more accessible consumer and commercial uses.

- A. Early Developments: The first 3D printers were primarily used for prototyping in industries like aerospace and automotive.

- B. Technological Advancements: Innovations such as improved printing speeds, higher resolution, and a broader range of printable materials have expanded the technology’s capabilities.

- C. Democratization: The rise of desktop 3D printers and affordable materials has made 3D printing accessible to hobbyists, educators, and small businesses.

3. Types of 3D Printing Technologies

Several 3D printing technologies cater to different needs and applications, each with its unique advantages.

- A. Fused Deposition Modeling (FDM): This widely used method involves melting and extruding thermoplastic filaments to build objects layer by layer.

- B. Stereolithography (SLA): SLA uses a laser to cure liquid resin into hardened plastic, offering high precision and smooth finishes.

- C. Selective Laser Sintering (SLS): SLS employs a laser to fuse powdered materials, such as nylon or metal, into solid structures, ideal for functional prototypes and end-use parts.

Applications of 3D Printing Across Industries

3D printing’s versatility allows it to be applied across various sectors, driving innovation and efficiency.

1. Healthcare and Medicine

3D printing has made significant strides in the healthcare sector, offering personalized solutions and improving patient outcomes.

- A. Customized Implants and Prosthetics: 3D printing enables the creation of implants and prosthetics tailored to individual patients, enhancing comfort and functionality.

- B. Bioprinting Tissues and Organs: Emerging bioprinting technologies aim to print living tissues and organs, potentially addressing the shortage of donor organs.

- C. Surgical Planning and Training Models: Surgeons use 3D-printed models of patient anatomy for better surgical planning and training, leading to more precise and efficient procedures.

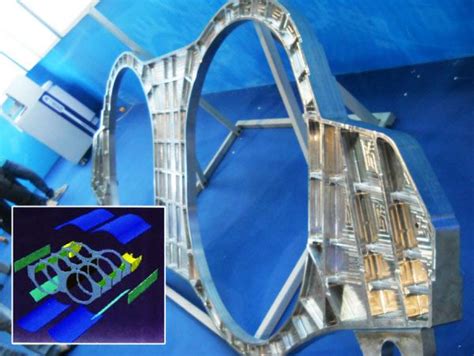

2. Aerospace and Automotive

The aerospace and automotive industries leverage 3D printing for lightweight, complex, and high-performance components.

- A. Lightweight Components: 3D printing allows for the design of lightweight parts without compromising strength, improving fuel efficiency and performance.

- B. Rapid Prototyping: Engineers can quickly produce prototypes for testing and validation, accelerating the development cycle.

- C. Spare Parts Production: On-demand production of spare parts reduces inventory costs and ensures availability, especially for older or specialized equipment.

3. Construction and Architecture

3D printing is revolutionizing construction by enabling the creation of intricate structures and reducing construction time and costs.

- A. Building Components: Complex architectural elements, such as facades and decorative features, can be 3D-printed with high precision.

- B. Entire Structures: Large-scale 3D printers can construct entire buildings, offering innovative solutions for affordable housing and sustainable construction.

- C. Custom Designs: Architects can experiment with unique and unconventional designs that would be challenging or impossible to achieve with traditional methods.

4. Education and Research

In education, 3D printing serves as a powerful tool for teaching and research, fostering creativity and hands-on learning.

- A. Interactive Learning: Students can design and print their projects, enhancing understanding of concepts in science, technology, engineering, and mathematics (STEM).

- B. Research Prototyping: Researchers use 3D printing to create prototypes for experiments, facilitating rapid iteration and innovation.

- C. Accessibility: Educational institutions can offer 3D printing resources, making advanced manufacturing techniques accessible to a broader audience.

5. Consumer Products and Fashion

The consumer market benefits from 3D printing through customization and the creation of unique products.

- A. Customized Accessories: Jewelry, eyewear, and other accessories can be personalized to individual preferences, offering a unique value proposition.

- B. Fashion Design: Designers use 3D printing to create avant-garde garments and accessories, pushing the boundaries of traditional fashion.

- C. Home Decor: Customized home decor items, such as lamps, vases, and furniture, enhance personalization and aesthetic appeal.

Benefits of 3D Printing

The adoption of 3D printing technology offers numerous advantages that drive its widespread use and ongoing innovation.

1. Customization and Personalization

3D printing excels in producing customized and personalized products, meeting specific needs and preferences.

- A. Tailored Solutions: Products can be designed to fit individual specifications, enhancing functionality and user satisfaction.

- B. Unique Designs: Designers and consumers can experiment with unique and unconventional designs, fostering creativity and innovation.

- C. Small Batch Production: 3D printing allows for efficient production of small batches without significant cost increases, ideal for niche markets.

2. Cost Efficiency

While initial investments in 3D printing equipment can be high, the long-term cost benefits are substantial.

- A. Reduced Material Waste: Additive manufacturing uses only the necessary material, minimizing waste compared to subtractive methods.

- B. Lower Inventory Costs: On-demand production reduces the need for large inventories, lowering storage and management costs.

- C. Streamlined Supply Chains: Shorter production cycles and localized manufacturing enhance supply chain efficiency and reduce transportation costs.

3. Speed and Agility

3D printing significantly accelerates the production process, enabling rapid prototyping and faster time-to-market.

- A. Quick Prototyping: Engineers and designers can quickly produce prototypes, allowing for faster testing and iteration.

- B. Accelerated Production: Complex parts can be printed in a single process, reducing the number of manufacturing steps and time required.

- C. Responsive Manufacturing: Businesses can respond swiftly to changing market demands and customer needs, maintaining competitiveness.

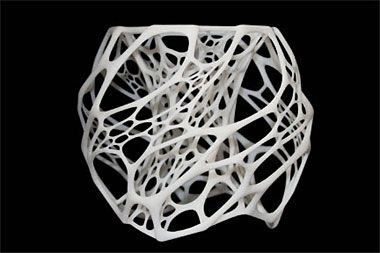

4. Innovation and Design Freedom

3D printing breaks traditional manufacturing constraints, enabling innovative designs and complex geometries.

- A. Complex Structures: Intricate and geometrically complex structures that are difficult or impossible to produce with traditional methods can be easily printed.

- B. Lightweight Designs: Optimized for strength and weight, 3D-printed parts can enhance performance in applications like aerospace and automotive.

- C. Integrated Functions: Multiple functions can be integrated into a single part, reducing assembly complexity and improving product performance.

Challenges Facing 3D Printing

Despite its numerous benefits, 3D printing also faces several challenges that need to be addressed for broader adoption and optimization.

1. Material Limitations

The range and properties of materials suitable for 3D printing are still limited compared to traditional manufacturing.

- A. Material Strength: Some 3D-printed materials may not match the strength and durability of their traditionally manufactured counterparts.

- B. Limited Material Variety: Although expanding, the variety of available materials for different applications remains limited.

- C. Cost of Specialized Materials: High-performance materials suitable for specific industries can be expensive, hindering widespread use.

2. Quality and Precision

Ensuring consistent quality and precision in 3D-printed parts is crucial, especially for critical applications.

- A. Surface Finish: 3D-printed objects often require post-processing to achieve smooth surfaces, adding time and cost.

- B. Dimensional Accuracy: Maintaining precise dimensions and tolerances can be challenging, particularly for complex geometries.

- C. Structural Integrity: Ensuring the structural integrity of printed parts, especially for load-bearing applications, is essential.

3. Intellectual Property Concerns

The ease of copying and replicating designs with 3D printing raises significant intellectual property (IP) issues.

- A. Design Protection: Protecting digital designs from unauthorized replication and distribution is a major concern.

- B. Counterfeiting Risks: The ability to print counterfeit products poses threats to brands and manufacturers.

- C. Legal Frameworks: Existing legal frameworks may not adequately address the unique challenges posed by 3D printing.

4. High Initial Costs

While 3D printing can reduce costs in the long run, the initial investment in equipment and training can be prohibitive.

- A. Equipment Costs: High-quality industrial 3D printers are expensive, limiting access for small businesses and startups.

- B. Training and Expertise: Effective use of 3D printing technology requires specialized skills and training, adding to the overall cost.

- C. Maintenance and Operation: Ongoing maintenance and operational costs can be significant, especially for complex or high-end printers.

Future Trends in 3D Printing

The future of 3D printing holds exciting possibilities as technology continues to advance and new applications emerge.

1. Advancements in Materials

The development of new materials will expand the capabilities and applications of 3D printing.

- A. Biodegradable Materials: Environmentally friendly materials will support sustainable manufacturing practices.

- B. High-Performance Polymers and Metals: Enhanced materials with superior properties will cater to demanding industries like aerospace and healthcare.

- C. Multi-Material Printing: The ability to print with multiple materials simultaneously will enable more complex and functional products.

2. Increased Integration with Other Technologies

3D printing will increasingly integrate with other emerging technologies, enhancing its functionality and applications.

- A. Internet of Things (IoT): Connecting 3D printers to IoT networks will enable real-time monitoring and optimization of the printing process.

- B. Artificial Intelligence (AI): AI-driven design and process optimization will improve the efficiency and quality of 3D-printed products.

- C. Robotics: Automated 3D printing systems with robotic arms will enhance precision and enable the creation of larger and more complex structures.

3. Expansion into New Industries

As 3D printing technology matures, its adoption will spread to new and diverse industries.

- A. Food Industry: 3D-printed food offers personalized nutrition and innovative culinary experiences.

- B. Fashion and Textiles: Advanced 3D printing techniques will enable the creation of intricate and customizable fashion items.

- C. Energy Sector: 3D printing can produce complex components for renewable energy systems, such as wind turbines and solar panels.

4. Sustainability and Eco-Friendly Practices

Sustainability will become a driving force in the evolution of 3D printing, promoting eco-friendly manufacturing practices.

- A. Recycling and Reuse: Efforts to recycle and reuse materials will reduce waste and support circular economy principles.

- B. Energy-Efficient Printing: Innovations aimed at reducing the energy consumption of 3D printers will enhance their environmental sustainability.

- C. Sustainable Material Development: The creation of new, eco-friendly materials will support the broader adoption of 3D printing in sustainable manufacturing.

5. Enhanced Accessibility and Democratization

Making 3D printing more accessible will democratize manufacturing, empowering individuals and small businesses.

- A. Affordable Desktop Printers: Continued reductions in the cost of desktop 3D printers will make the technology accessible to a wider audience.

- B. User-Friendly Software: Improvements in design and printing software will simplify the 3D printing process, making it easier for non-experts to create complex designs.

- C. Community and Sharing Platforms: Online communities and platforms for sharing designs and knowledge will foster collaboration and innovation.

3D Printing in Sustainable Development

3D printing plays a significant role in advancing sustainable development goals by promoting efficient resource use, reducing waste, and enabling innovative solutions.

1. Reducing Waste and Resource Efficiency

Additive manufacturing inherently produces less waste compared to traditional subtractive methods, contributing to more sustainable production practices.

- A. Minimal Material Usage: Only the necessary material is used in 3D printing, minimizing excess waste and conserving resources.

- B. On-Demand Production: Manufacturing products as needed reduces overproduction and excess inventory, lowering overall resource consumption.

- C. Recycling Capabilities: Some 3D printers can reuse materials from discarded prints, further enhancing sustainability.

2. Sustainable Product Design

3D printing allows for the creation of optimized and sustainable product designs that are lighter, stronger, and more efficient.

- A. Lightweight Structures: Optimized geometries reduce material usage and improve energy efficiency, particularly in transportation industries.

- B. Modular Designs: Interchangeable and easily repairable parts extend the lifespan of products, reducing the need for frequent replacements.

- C. Renewable Materials: The use of biodegradable and renewable materials supports environmentally friendly manufacturing practices.

3. Localized Manufacturing

3D printing enables localized production, which can reduce transportation emissions and support local economies.

- A. Decentralized Production: Manufacturing products closer to the point of use minimizes transportation distances and associated carbon emissions.

- B. Supply Chain Resilience: Localized manufacturing enhances supply chain resilience by reducing dependence on global logistics and mitigating risks related to disruptions.

- C. Economic Empowerment: Supporting local production fosters economic growth and job creation within communities.

Overcoming Challenges in 3D Printing Adoption

Addressing the challenges associated with 3D printing is crucial for its widespread adoption and optimization across industries.

1. Enhancing Material Properties

Improving the range and properties of printable materials is essential to meet the demands of various applications.

- A. Research and Development: Investing in R&D to develop new materials with enhanced strength, flexibility, and durability will expand 3D printing’s applicability.

- B. Standardization: Establishing material standards ensures consistency and reliability in 3D-printed products, fostering trust and adoption.

- C. Collaboration with Material Scientists: Partnering with material scientists can drive innovations in printable materials tailored to specific industry needs.

2. Improving Printing Speed and Scalability

Increasing the speed and scalability of 3D printing processes is vital for industrial applications and mass production.

- A. Advanced Printer Designs: Developing faster printing technologies and optimizing printer architectures can enhance production speeds.

- B. Parallel Printing Techniques: Utilizing multiple print heads or simultaneous printing processes can increase output without compromising quality.

- C. Automation and Robotics: Integrating automation and robotics with 3D printing can streamline production workflows and improve scalability.

3. Ensuring Quality and Reliability

Maintaining consistent quality and reliability in 3D-printed products is critical, especially for high-stakes applications.

- A. Quality Control Systems: Implementing robust quality control systems, including real-time monitoring and inspection, ensures the reliability of printed parts.

- B. Certification and Standards: Developing industry-specific certifications and standards for 3D-printed products fosters trust and compliance.

- C. Continuous Improvement: Adopting a culture of continuous improvement and feedback loops can help identify and address quality issues promptly.

4. Addressing Intellectual Property Issues

Protecting intellectual property in the era of 3D printing requires innovative solutions and regulatory frameworks.

- A. Digital Rights Management: Implementing DRM technologies can prevent unauthorized access and copying of digital design files.

- B. Legal Protections: Updating legal frameworks to address 3D printing-related IP issues ensures that creators and manufacturers are protected.

- C. Industry Collaboration: Collaborating across industries to establish best practices and standards for IP protection can mitigate risks associated with 3D printing.

The Future of 3D Printing: Innovations and Possibilities

As 3D printing technology continues to evolve, the future holds numerous exciting innovations and possibilities that will further integrate additive manufacturing into everyday life.

1. Multi-Material and Multi-Color Printing

The ability to print with multiple materials and colors simultaneously will enhance the versatility and functionality of 3D-printed objects.

- A. Functional Integration: Combining different materials in a single print can create objects with varied properties, such as flexible joints and rigid structures.

- B. Aesthetic Enhancements: Multi-color printing allows for more visually appealing designs, expanding applications in consumer products and art.

- C. Prototyping Versatility: Designers can create more realistic and functional prototypes, improving the design and testing process.

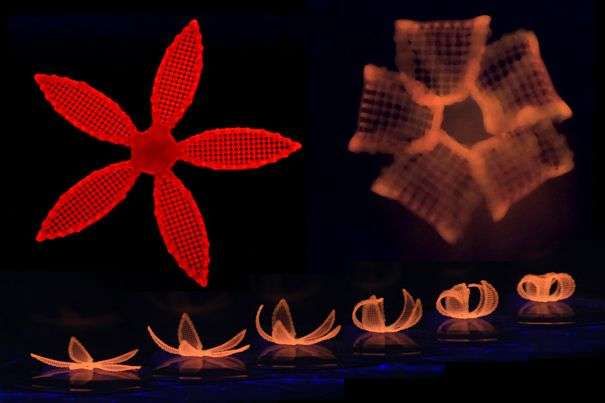

2. 4D Printing: Time-Responsive Objects

4D printing involves creating objects that can change shape or function over time in response to external stimuli, adding a new dimension to additive manufacturing.

- A. Shape-Shifting Structures: Objects can adapt their shape based on environmental conditions, enhancing functionality and adaptability.

- B. Responsive Medical Devices: Time-responsive medical devices can adjust their behavior based on patient needs or physiological changes.

- C. Smart Textiles: 4D-printed textiles can respond to temperature, moisture, or other factors, enabling innovative fashion and functional apparel.

3. Integration with Smart Technologies

Combining 3D printing with smart technologies, such as IoT and AI, will create more intelligent and responsive manufacturing systems.

- A. Smart Manufacturing: Integrating sensors and connectivity into 3D printers enables real-time monitoring and optimization of the printing process.

- B. AI-Driven Design: AI can assist in designing optimized and innovative 3D-printed structures, enhancing efficiency and creativity.

- C. Predictive Maintenance: AI-powered predictive maintenance systems can foresee and prevent printer malfunctions, ensuring continuous and reliable operations.

4. Advanced Bioprinting and Medical Applications

Bioprinting continues to advance, offering groundbreaking possibilities in healthcare and medicine.

- A. Organ Regeneration: Future bioprinting technologies may enable the creation of fully functional human organs, addressing organ shortages.

- B. Personalized Medicine: Customized drug delivery systems and implants tailored to individual patient needs will enhance treatment outcomes.

- C. Tissue Engineering: Bioprinting of tissues can support regenerative medicine, wound healing, and advanced surgical techniques.

5. Sustainable and Eco-Friendly 3D Printing

The future of 3D printing emphasizes sustainability and eco-friendly practices, aligning with global environmental goals.

- A. Renewable Materials: Continued development of biodegradable and renewable materials will reduce the environmental impact of 3D printing.

- B. Energy-Efficient Processes: Innovations aimed at reducing the energy consumption of 3D printers will enhance their sustainability.

- C. Circular Economy Integration: 3D printing will play a pivotal role in the circular economy by enabling recycling, reuse, and sustainable production practices.

Conclusion

3D printing stands at the forefront of a manufacturing revolution, offering innovative solutions that reshape industries, enhance customization, and promote sustainability. Its transformative potential spans across healthcare, aerospace, construction, education, and consumer products, driving efficiency, creativity, and economic growth.

However, realizing the full benefits of 3D printing requires addressing existing challenges related to material limitations, quality assurance, intellectual property, and initial costs. By fostering continuous innovation, enhancing material properties, and developing robust regulatory frameworks, the path forward for 3D printing is promising and expansive.

As technology advances, the integration of multi-material printing, 4D printing, smart technologies, and sustainable practices will unlock new possibilities, further embedding 3D printing into the fabric of modern manufacturing and everyday life. Embracing this technology with a focus on innovation, quality, and sustainability will enable businesses and communities to harness its full potential, paving the way for a future defined by creativity, efficiency, and responsible manufacturing.